- 24 Dec 2025

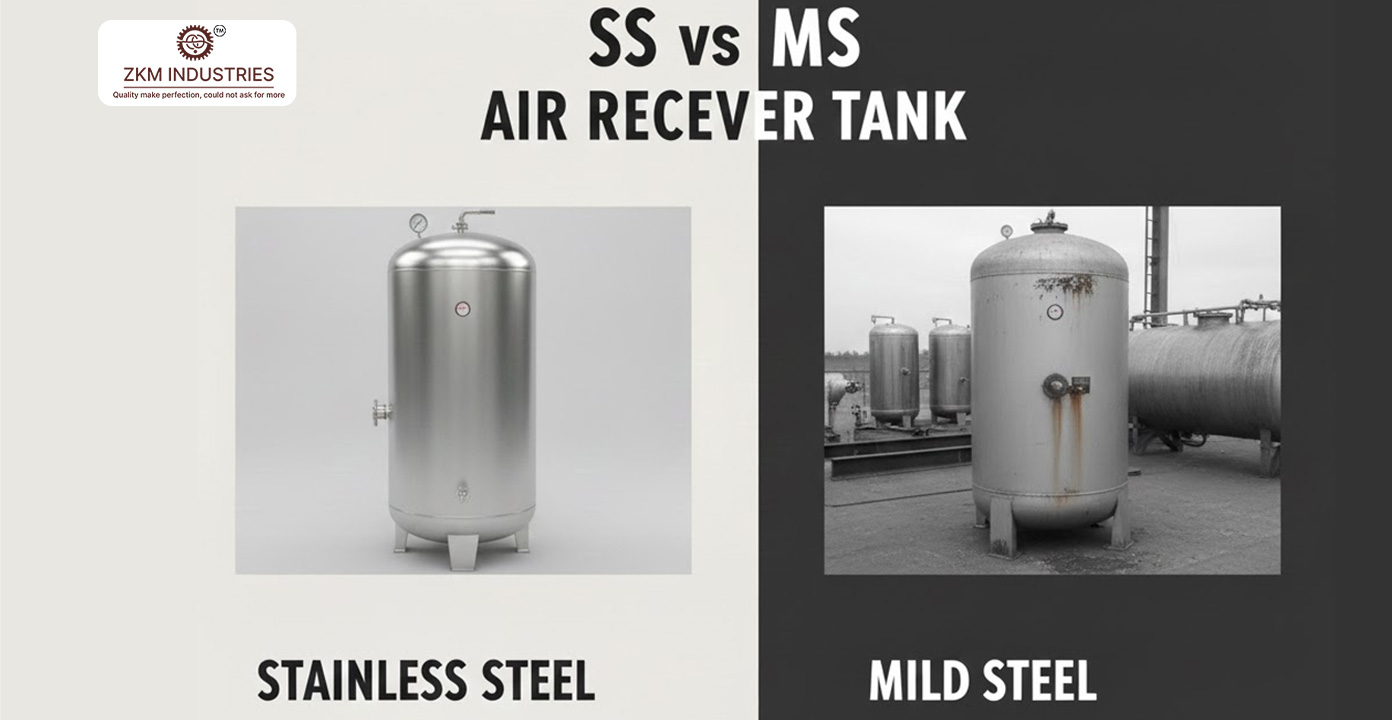

Stainless Steel vs Mild Steel Storage Tanks — Material Comparison

Storage tanks play a vital role in industrial operations. They are used to store liquids, gases, and sometimes powders safely and efficiently. Whether it is chemicals, water, oils, or pharmaceutical ingredients, having the right storage tank ensures smooth production processes and maintains product quality.

Choosing the right material for a storage tank is crucial. The material impacts the tank’s durability, safety, and cost-efficiency. A tank that is resistant to corrosion and chemical reactions will last longer, reduce maintenance costs, and protect the stored substances from contamination.

Since 2024, ZKM Industries has been a trusted manufacturer and supplier of high-quality industrial tanks. Based in Ahmedabad, Gujarat, ZKM Industries provides tanks that meet stringent industry standards, catering to a wide range of sectors including chemical, pharmaceutical, food processing, and oil & gas.

Overview of Storage Tank Materials

Stainless Steel

Stainless steel is an alloy made primarily of iron, carbon, and chromium. It is highly valued for its resistance to corrosion and strength, making it ideal for industries where hygiene and durability are essential. Common uses include storing chemicals, edible oils, pharmaceutical solutions, and potable water.

Mild Steel

Mild steel is a type of carbon steel with low carbon content. It is strong, easy to fabricate, and more cost-effective compared to stainless steel. Mild steel tanks are widely used in industries such as oil storage, water treatment, and general chemical storage where high corrosion resistance is not a strict requirement.

Industries Using Stainless Steel & Mild Steel

Both stainless steel and mild steel tanks are common in several sectors:

- Chemical industry: Storage of acids, solvents, and other chemicals.

- Pharmaceuticals: Maintaining purity in liquid medicines and solutions.

- Food processing: Oils, beverages, and dairy products.

- Oil & Gas: Crude oil, fuels, and lubricants.

Stainless Steel Storage Tanks

Composition & Properties

Stainless steel storage tanks are made with a mix of iron, carbon, and chromium, sometimes including nickel or molybdenum for enhanced properties. Their key characteristics include:

- Corrosion resistance: Protects the tank from rust and chemical reactions.

- Strength: Can withstand pressure and heavy use.

- Hygienic properties: Easy to clean, suitable for high-purity liquid storage.

Advantages of Stainless Steel Tanks

- High durability: Can last decades with proper maintenance.

- Resistance to rust and chemicals: Ideal for acidic or corrosive liquids.

- Low maintenance: Requires minimal cleaning and upkeep.

- Suitable for high-purity liquids: Safe for food, pharmaceuticals, and drinking water.

Disadvantages of Stainless Steel Tanks

- Higher cost: More expensive than mild steel tanks.

- Heavier and harder to fabricate: Can be challenging to transport and install in some cases.

Common Applications

- Chemical storage: Acids, alkalis, solvents, and other chemicals.

- Edible oils: Maintaining hygiene and preventing contamination.

- Pharmaceuticals: Storing syrups, medicines, and active ingredients.

- Water storage: Drinking water, potable water for industries, and purified water.

Mild Steel Storage Tanks

Composition & Properties

Mild steel is primarily an alloy of iron with a small percentage of carbon. This composition gives it good mechanical strength and workability, making it suitable for a variety of industrial storage applications. However, unlike stainless steel, mild steel is susceptible to corrosion if not coated or lined properly.

Advantages of Mild Steel Tanks

- Cost-effective: Lower initial investment compared to stainless steel.

- Easy to fabricate and weld: Can be shaped and installed with relative ease.

- Strong mechanical properties: Handles pressure and structural loads well.

Disadvantages of Mild Steel Tanks

- Prone to corrosion: Requires protective coatings or linings to prevent rust.

- Higher maintenance: Regular inspection, painting, or lining needed to ensure longevity.

- Not ideal for highly corrosive substances: Chemicals or acidic liquids may damage the tank over time.

Common Applications

- Industrial water storage: Non-potable or treated water.

- Fuel storage: Diesel, petrol, or other fuels where corrosion is not a major concern.

- Low-corrosion chemical storage: Chemicals that are non-acidic or mildly reactive.

Stainless Steel vs Mild Steel — Side-by-Side Comparison

| Feature | Stainless Steel Tanks | Mild Steel Tanks |

|---|---|---|

| Corrosion Resistance | Excellent | Moderate to Poor (requires coating) |

| Durability | Very High | Moderate |

| Cost | High | Low |

| Maintenance | Low | High |

| Weight | Heavy | Lighter |

| Applications | Chemicals, Food & Pharma | Water, Fuel, Non-corrosive liquids |

This comparison helps industries quickly identify which tank material suits their specific needs, balancing cost, durability, and safety.

Factors to Consider When Choosing the Right Material

Selecting the right storage tank material depends on several critical factors:

- Type of liquid to be stored: Corrosive liquids such as acids require stainless steel, while non-corrosive liquids like water or fuel may be safely stored in mild steel.

- Temperature requirements: Some liquids need tanks that can withstand high or low temperatures without degrading.

- Budget constraints: Stainless steel offers superior longevity but comes at a higher cost. Mild steel is more budget-friendly initially.

- Longevity and maintenance requirements: Stainless steel requires less maintenance, whereas mild steel may need regular coatings and inspections.

- Industry standards and compliance requirements: Certain industries like pharmaceuticals and food processing demand tanks made from hygienic, corrosion-resistant materials such as stainless steel.

► Which tank is better for chemical storage?

Stainless steel tanks are ideal for storing corrosive chemicals due to their excellent corrosion resistance. Mild steel tanks can store non-corrosive chemicals if coated properly.

► How long does a stainless steel tank last vs a mild steel tank?

Stainless steel tanks can last 20–30 years or more with proper maintenance. Mild steel tanks typically last 10–15 years, depending on usage and protective coatings.

► Can mild steel tanks be coated to prevent corrosion?

Yes, mild steel tanks can be coated with epoxy, enamel, or other protective linings to improve corrosion resistance and extend their lifespan.

► Are stainless steel tanks more expensive than mild steel tanks?

Yes, stainless steel tanks have a higher initial cost due to their material and durability. However, they offer lower maintenance costs over time.

► Can stainless steel tanks store food and beverages safely?

Absolutely. Stainless steel is hygienic, non-reactive, and corrosion-resistant, making it ideal for food, dairy, and beverage storage.

► Are mild steel tanks suitable for water storage?

Yes, mild steel tanks can store water effectively. However, they may require coatings or linings to prevent rust over time.

► What industries use stainless steel storage tanks?

Common industries include chemical, pharmaceutical, food processing, beverage, and oil & gas sectors.

► What industries use mild steel storage tanks?

Mild steel tanks are widely used in water treatment plants, fuel storage facilities, and general non-corrosive liquid storage industries.

► Can tanks be customized according to industrial requirements?

Yes, both stainless steel and mild steel tanks can be customized in size, shape, coating, and fittings according to specific industrial needs.

► What maintenance is required for stainless steel vs mild steel tanks?

Stainless steel tanks require minimal maintenance, mostly routine cleaning. Mild steel tanks need regular inspection, painting, or coating maintenance to prevent corrosion.

► How do I choose the right tank material for my industry?

Consider the type of liquid, corrosiveness, temperature, budget, and industry standards. Corrosive liquids require stainless steel, while non-corrosive liquids can often be stored in mild steel.

► Are ZKM Industries tanks compliant with industrial standards?

Yes, ZKM Industries manufactures tanks that are industry-compliant, high-quality, and GST verified, ensuring safety and reliability.

► Can mild steel tanks be used for acidic chemicals?

Mild steel tanks are not recommended for highly acidic or corrosive chemicals unless lined with a protective coating. Stainless steel is the safer choice.

► What is the weight difference between stainless steel and mild steel tanks?

Stainless steel tanks are heavier due to their density, while mild steel tanks are lighter and easier to transport.

► Do stainless steel tanks require lining for storage?

Generally, no lining is required for stainless steel tanks, as the material itself is corrosion-resistant and hygienic.