- 25 Dec 2025

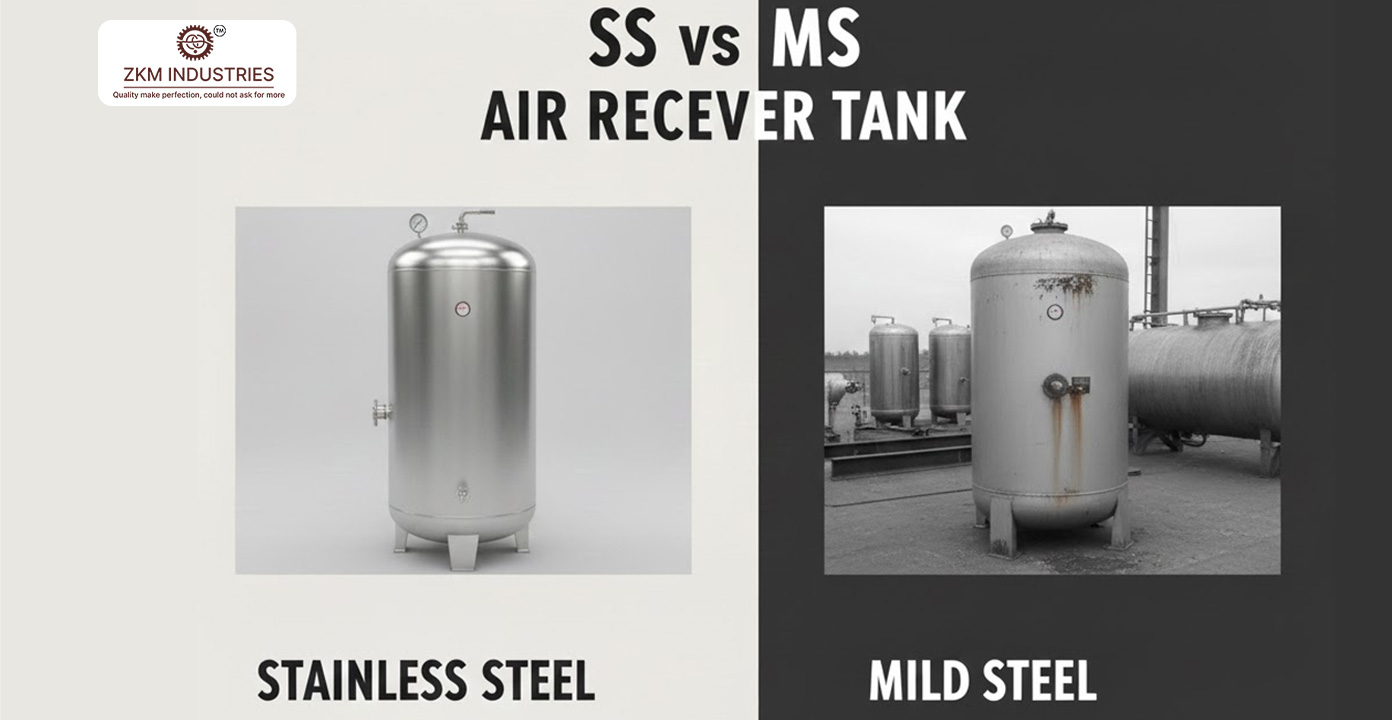

SS vs MS Air Receiver Tank — Key Differences and Applications

Air receiver tanks play a crucial role in many industrial operations. These tanks act as storage units for compressed air, ensuring smooth and efficient performance of pneumatic tools and machinery. Without a properly sized and high-quality air receiver tank, industries may face inconsistent pressure, reduced equipment lifespan, and higher energy consumption.

ZKM Industries, based in Bakrol, Ahmedabad, has earned a strong reputation as a trusted manufacturer and supplier of high-quality Stainless Steel (SS) and Mild Steel (MS) air receiver tanks. With a focus on durability, precision, and industry standards, ZKM Industries helps businesses choose tanks that meet their operational needs.

The purpose of this blog is to guide industries in selecting the right air receiver tank material, understanding the benefits of SS and MS tanks, and making informed decisions for optimal performance.

Overview of Air Receiver Tanks

Definition and Primary Function:

An air receiver tank is a pressure vessel designed to store compressed air from a compressor. It acts as a buffer between the air compressor and the air-consuming equipment, maintaining a consistent air supply.

Role in Compressed Air Systems:

- Pressure Regulation: Maintains stable pressure to avoid sudden surges or drops.

- Air Storage: Provides a reservoir of compressed air to handle peak demand efficiently.

- Efficiency: Reduces wear on compressors and lowers energy consumption by minimizing the need for continuous operation.

Key Industries Using Air Receiver Tanks:

Air receiver tanks are widely used in industries where compressed air is essential:

- Automotive: For spray painting, assembly lines, and pneumatic tools.

- Manufacturing: For machinery operation, material handling, and robotics.

- Pharmaceuticals & Food Processing: For hygienic operations requiring clean, oil-free air.

- Textiles, Chemicals, and Electronics: For various production processes requiring precise air control.

What is a Stainless Steel (SS) Air Receiver Tank?

Material Composition and Properties:

Stainless steel tanks are made primarily from iron, chromium, and nickel alloys, giving them a smooth, corrosion-resistant surface. They are highly durable and can withstand both high pressure and harsh environmental conditions.

Advantages of SS Tanks:

- Corrosion Resistance: Ideal for environments with moisture or chemicals.

- Durability: Long-lasting performance with minimal maintenance.

- Hygienic Applications: Suitable for industries requiring clean, contaminant-free air (pharmaceuticals, food & beverage).

Typical Applications and Industries:

SS air receiver tanks are preferred where hygiene, corrosion resistance, and longevity are critical:

- Food processing plants

- Pharmaceutical manufacturing

- Chemical industries

- High-end manufacturing units requiring clean and dry air

What is a Mild Steel (MS) Air Receiver Tank?

Material Composition and Properties:

Mild steel tanks are made from low carbon steel, which is strong, easy to fabricate, and cost-effective. Though less resistant to corrosion than stainless steel, MS tanks are ideal for general industrial use.

Advantages of MS Tanks:

- Cost-Effective: Lower initial investment compared to SS tanks.

- Easy Fabrication: Can be customized in size and shape to meet specific requirements.

- Adequate Performance: Works well in dry, non-corrosive environments.

Typical Applications and Industries:

MS air receiver tanks are widely used in industries where cost efficiency and standard performance are important:

- Automotive workshops and service centers

- General manufacturing units

- Construction sites and industrial plants

- Non-hygienic applications where corrosion is not a major concern

Key Differences Between SS and MS Air Receiver Tanks

Choosing the right material for an air receiver tank depends on various factors such as corrosion resistance, durability, cost, maintenance, and the intended application. Here’s a detailed comparison of Stainless Steel (SS) and Mild Steel (MS) tanks:

| Feature | Stainless Steel (SS) | Mild Steel (MS) |

|---|---|---|

| Corrosion Resistance | High: SS tanks resist rust and corrosion even in humid or chemically aggressive environments. | Moderate: MS tanks can rust if exposed to moisture; often require a protective coating like paint or enamel. |

| Durability | Long-lasting: SS tanks maintain structural integrity over many years, making them ideal for critical operations. | Moderate: MS tanks are strong but can deteriorate faster in harsh environments. |

| Cost | Higher: SS material and manufacturing costs are more, but they provide long-term savings through durability and low maintenance. | Lower: MS tanks are cheaper to produce and buy initially, suitable for budget-conscious operations. |

| Maintenance | Low: SS tanks need minimal upkeep as they resist corrosion and contamination. | Medium to High: MS tanks require regular inspections, painting, or coating to prevent rust. |

| Suitable Applications | Food, Pharmaceuticals, Chemicals: SS tanks ensure hygienic and contamination-free storage. | General Industrial Use: MS tanks are ideal for workshops, factories, or construction sites where air quality and hygiene are not critical. |

Corrosion Resistance

Stainless Steel: SS tanks are highly resistant to corrosion, which makes them perfect for humid or chemically active environments. For example, in a pharmaceutical plant, compressed air must remain clean and free from rust particles, which SS tanks can ensure.

Mild Steel: MS tanks, on the other hand, can corrode when exposed to moisture or chemicals. In a metal fabrication workshop, an MS tank might need periodic painting or epoxy coating to prevent rust over time.

Durability

Stainless Steel: SS tanks have excellent longevity and can withstand high pressures and environmental stress without deforming. For instance, a food processing plant using SS tanks can operate continuously for years without replacing the tank.

Mild Steel: MS tanks are reasonably strong but less resistant to long-term wear and corrosion. For example, a general manufacturing plant using MS tanks may need to replace the tanks after several years due to rust or surface damage.

Cost

Stainless Steel: The initial investment is higher due to material costs, but the long-term savings on maintenance and replacement often make SS tanks cost-effective for critical applications.

Mild Steel: MS tanks are less expensive upfront, making them suitable for industries where the budget is tight, and the tank’s longevity is not as critical. For example, a construction site may prefer MS tanks for temporary setups.

Maintenance

Stainless Steel: SS tanks require minimal maintenance. There’s no need for regular painting or rust prevention. This is ideal for pharmaceutical or chemical plants, where cleaning and maintenance downtime can be costly.

Mild Steel: MS tanks need routine maintenance to prevent rust, including painting, inspection, and occasional repairs. For example, in a vehicle repair workshop, MS tanks must be checked frequently to avoid leaks or contamination.

Suitable Applications

Stainless Steel: Best suited for industries requiring hygiene and corrosion resistance, such as:

- Food and beverage processing

- Pharmaceutical manufacturing

- Chemical industries

Mild Steel: Ideal for general industrial use where cost-efficiency is more important than corrosion resistance, such as:

- Automotive workshops

- Non-hygienic manufacturing plants

- Construction sites

Factors to Consider When Choosing Between SS and MS Tanks

Selecting the right air receiver tank requires careful evaluation of several factors:

1. Environmental Conditions:

- Humidity: High moisture levels can cause mild steel tanks to rust, while stainless steel tanks remain resistant. For instance, coastal or chemical plant environments benefit from SS tanks.

- Chemical Exposure: If the tank will store air used in chemical processing or corrosive environments, SS tanks are ideal due to their corrosion resistance.

2. Budget Constraints:

- MS tanks are more cost-effective upfront, making them suitable for budget-sensitive operations.

- SS tanks have a higher initial cost but lower long-term maintenance, which can make them more economical in the long run.

3. Longevity and Maintenance Requirements:

- SS tanks require minimal maintenance and can last decades in harsh conditions.

- MS tanks need regular inspection, painting, or coating to prevent rust and extend lifespan.

4. Compliance with Industry Standards:

- Industries like pharmaceuticals, food processing, and chemicals often require tanks to meet strict hygiene and safety standards, which favors stainless steel.

- For general manufacturing or workshops, MS tanks can meet the standard industrial codes without excessive cost.

Applications of SS vs MS Air Receiver Tanks

Stainless Steel (SS) Tanks:

- Industries: Chemical, pharmaceutical, food & beverage.

- Real-life Use Case: A pharmaceutical plant uses SS air receiver tanks to ensure compressed air remains contaminant-free, critical for sterile production. Similarly, a food processing factory relies on SS tanks to prevent rust contamination in edible products.

Mild Steel (MS) Tanks:

- Industries: General manufacturing, automotive workshops, small-scale industries.

- Real-life Use Case: An automobile service center uses MS tanks for compressed air tools and spray painting, where corrosion resistance is less critical. Small-scale manufacturing units often use MS tanks for general pneumatic operations due to cost efficiency.

This comparison highlights that choosing the tank material depends heavily on the industry, environmental conditions, and budget.

Why Choose ZKM Industries for Air Receiver Tanks

1. Expertise and Experience:

- Since 2024, ZKM Industries has been a trusted name in manufacturing high-quality SS and MS air receiver tanks, serving diverse industrial needs.

2. Customization Options:

- ZKM Industries provides tailored solutions, designing tanks in various capacities, sizes, and specifications according to client requirements.

3. Trusted and Verified Manufacturer:

- Based in Bakrol, Ahmedabad, ZKM Industries is GST verified and serves major industrial markets across India, ensuring reliability and compliance.

4. Commitment to Quality and Timely Delivery:

- Every tank undergoes stringent quality checks to meet industry standards.

- The company emphasizes customer satisfaction, timely delivery, and post-sales support, making it a preferred choice for industrial air storage solutions.

Choosing the right air receiver tank is a critical decision for industrial operations. Stainless Steel (SS) tanks stand out for their corrosion resistance, durability, and suitability for hygienic applications, making them ideal for food processing, pharmaceuticals, and chemical industries. On the other hand, Mild Steel (MS) tanks are cost-effective, easy to fabricate, and suitable for general industrial use, such as in automotive workshops, small-scale manufacturing, and construction sites.

When selecting between SS and MS tanks, industries should consider environmental conditions, budget, maintenance requirements, and compliance with industry standards. Evaluating these factors ensures the tank chosen aligns perfectly with operational needs and long-term efficiency.

For businesses looking for high-quality, reliable, and customizable air receiver tanks, ZKM Industries offers expert guidance, tailored solutions, and adherence to stringent quality standards.